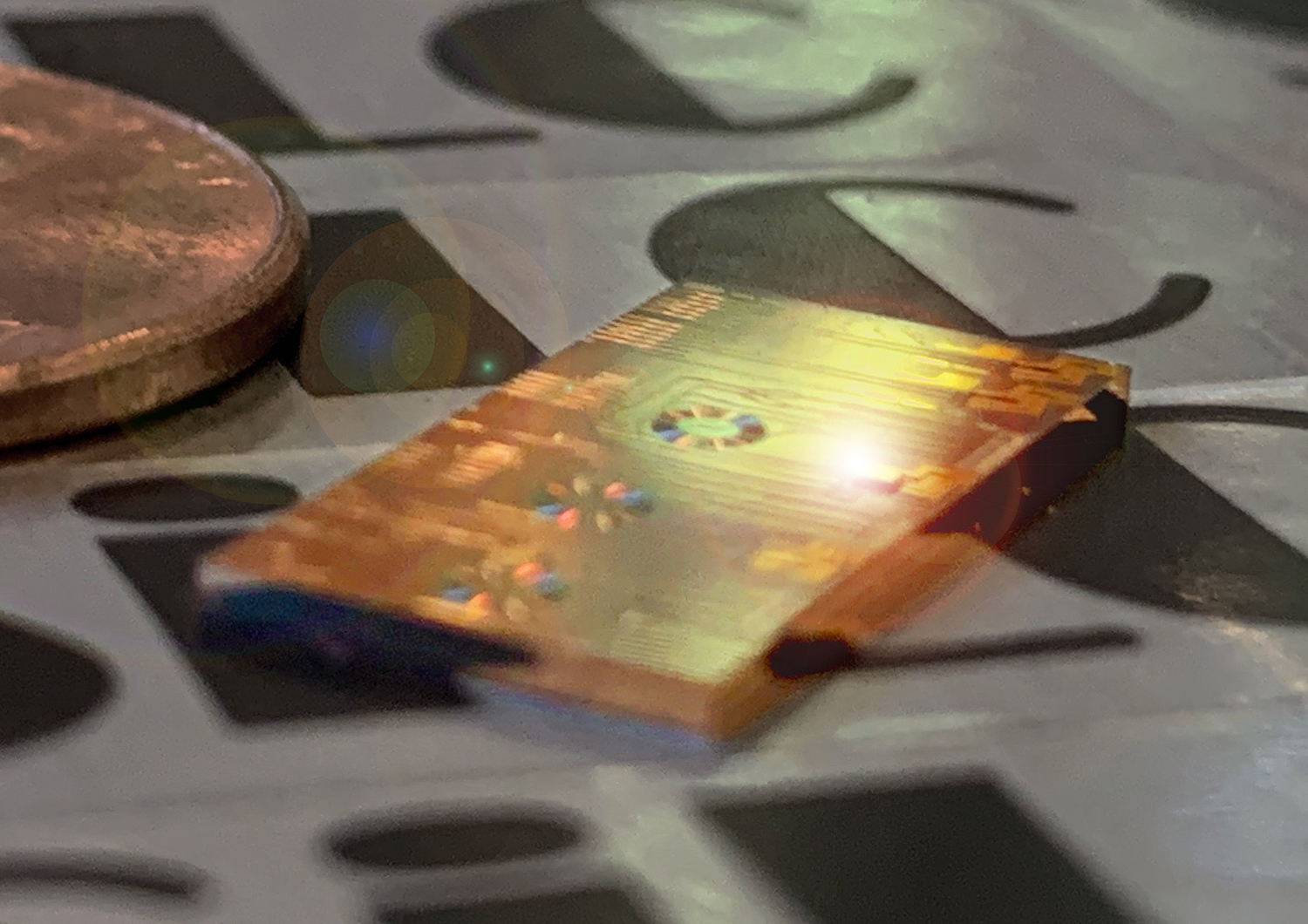

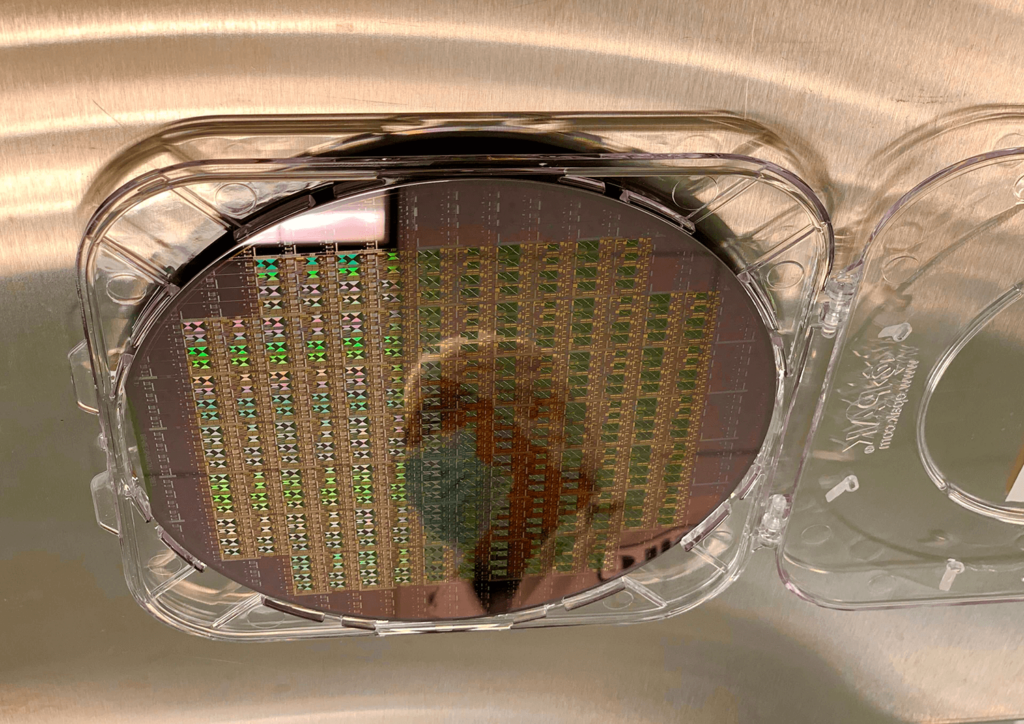

Current 3D vision technology relies on high power lasers at the 905-nanometer wavelength and highly sensitive detectors, using a Time of Flight (TOF) architecture. These early technologies have performed adequately to enable early deployments in autonomous vehicle trials. However, costly assembly processes have limited their resolution and cost-effective scaling, eye safety concerns have restricted their range and multiuser crosstalk will most likely hamper their widespread usage. It is broadly accepted that a transition to Frequency Modulated Continuous Wave (FMCW) technology at 1550 nanometer wavelength is needed to address eye safety regulatory concerns and enable volume deployment with minimal multi-user interference. Extensive usage of this approach has been prevented in the past due to the cost and number of components needed. SiLC’s silicon photonics integration platform offers a cost-effective solution by integrating all the high-performance components needed into a single silicon chip through mature semiconductor fabrication processes offering a low cost, compact, and low power solution. Silicon manufacturing offers affordable high-volume scaling of complex devices and technologies. SiLC is advancing the future of Machine Vision, to enable machines to see like humans, with its FMCW-based LiDAR vision solution – Eyeonic.